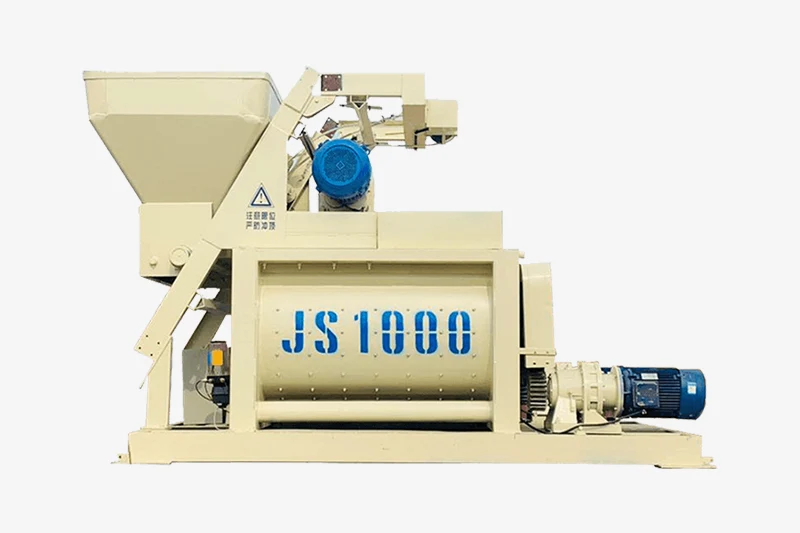

The rubber wheel friction transmission is adopted, which has low noise, stable operation, convenient operation and movement, good mixing quality and high production efficiency. The mixer can mix plastic and semi-dry concrete. It is a practical machine for large aggregate concrete construction and is used in road engineering, bridge engineering, construction engineering, hydropower engineering, small and medium-sized prefabricated component factories, indoor and outdoor decoration and other fields.

Advantages:

1. Smooth operation

2. Stable dual drive force output

3. Few vulnerable parts of the equipment are easy to replace 4. Short feeding time and higher efficiency The machine can be equipped with cement metering, fly ash metering, and additive metering to achieve accurate batching.