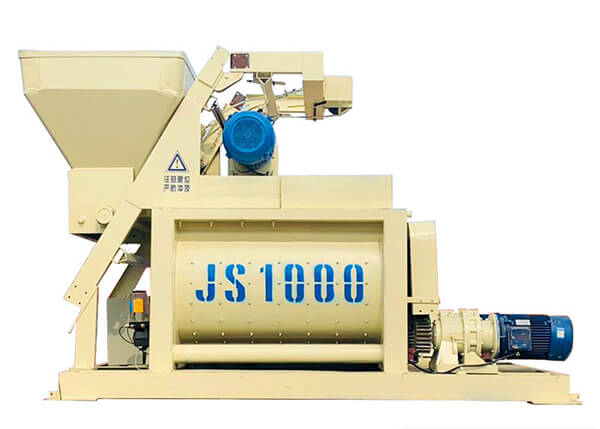

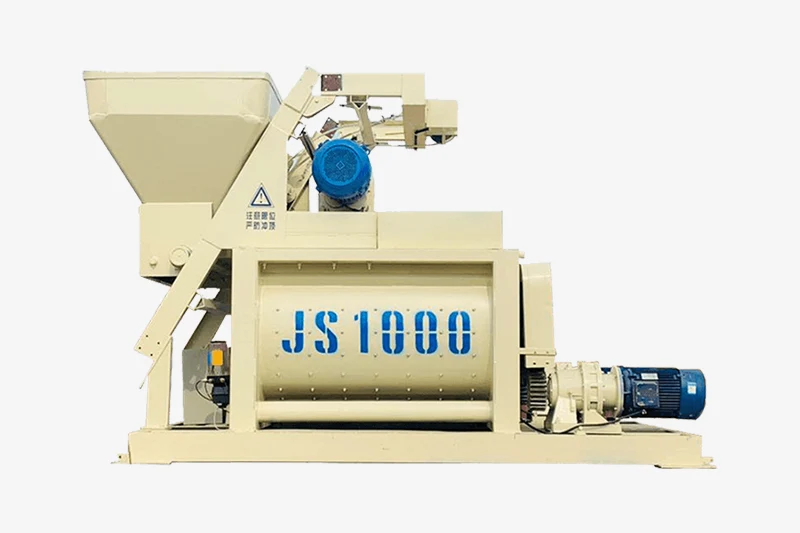

JS1000 forced mixer is used in large and medium-sized prefabricated component plants and industrial and civil construction projects such as highways, bridges, water conservancy, and docks. It can mix plastic, dry hard, lightweight aggregate concrete and various mortars, mortars, etc.;

Advantages:

1. The electric lubricating oil pump can use NLGI second-grade or third-grade lubricating oil to make the shaft end seal better and more fuel-efficient;

2. A variety of blade angles meet customer needs and the mixing quality is better;

3. The slump of concrete in the mixer can be monitored and changed in real time, providing users with high-quality concrete;

4. Reduce the friction and impact of materials, and the material flow is smoother

5. Shorten the mixing time, improve the mixing efficiency, and reduce the mixing energy consumption

6. It has the advantages of high degree of automation, good mixing quality, high efficiency, low energy consumption, low noise, easy operation, fast unloading speed, long service life of liner and blades, and convenient maintenance.