Client Background

A building materials factory in Yunnan mainly produces various specifications of building bricks, including standard bricks, hollow bricks, and permeable bricks. These products are primarily supplied to local construction engineering companies. With the rapid development of the local construction industry, demand for building bricks continues to increase. The company's existing production equipment is no longer able to meet market demand. In particular, problems such as uneven mixing in the mixer and low production efficiency in the brick-making machines have resulted in inconsistent product quality and long production cycles, seriously impacting the company's market competitiveness. Therefore, the company plans to purchase a batch of high-efficiency, high-quality mixers and brick-making machines to expand production and improve product quality and efficiency.

Client Requirements

The mixer must have a strong mixing capacity to thoroughly mix raw materials such as cement, sand, gravel, and water, ensuring consistent concrete quality and meeting brick-making process requirements. Furthermore, the mixer must be highly efficient and able to provide a sufficient supply of raw materials for the brick-making machines.

The brick-making machines must be highly efficient, capable of producing at least 50,000 bricks per day. Furthermore, the bricks produced by the brick-making machines must be strong, smooth, and have minimal dimensional error, meeting national standards for building bricks. The two sets of equipment must be used in conjunction to ensure coordinated and stable operation, minimize equipment downtime, and improve overall production efficiency.

The equipment is simple to operate and maintain, reducing employee workload and maintenance costs.

Solution

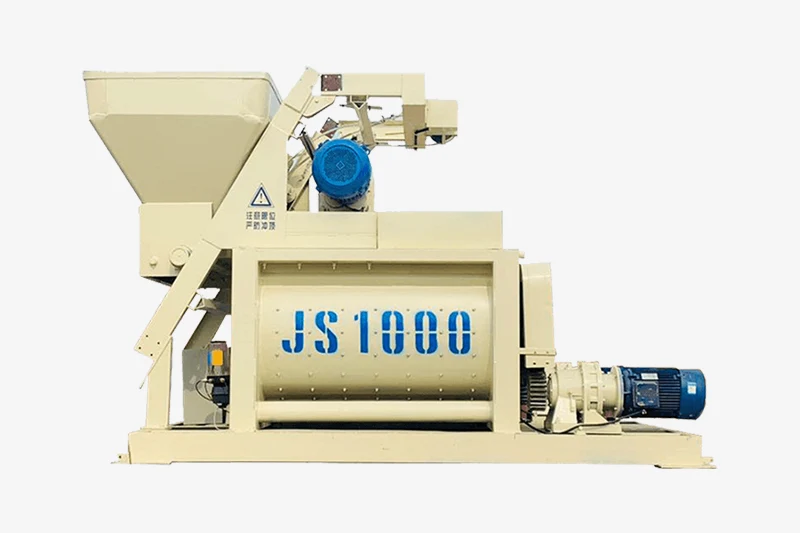

Based on the customer's production needs and product characteristics, we provided a complete mixing and brick-making solution, recommending our JS Series twin-shaft concrete mixer and QT Series fully automatic block-making machine (brick-making machine).

The JS Series twin-shaft concrete mixer utilizes a twin-shaft forced mixing method. Its mixing blades are constructed of high-strength, wear-resistant materials, resulting in uniform mixing and high efficiency. The equipment is equipped with a precise batching system that accurately controls the amount of various raw materials used according to specific concrete recipes, ensuring consistent concrete quality. The mixer's well-designed inlet and outlet facilitates easy loading and rapid discharge, achieving an hourly mixing output of up to 50 cubic meters, providing an ample supply of raw materials for the brick-making machine. Furthermore, the equipment utilizes a PLC control system for simple and convenient operation, automatically performing processes such as loading, mixing, and discharging, significantly reducing employee workload.

QT Series Fully Automatic Block Forming Machine (Brick Making Machine): This brick making machine utilizes advanced hydraulic transmission technology, offering high forming pressure, high production efficiency, and excellent product quality. Equipped with a fully automatic material distribution and demolding system, the machine automatically distributes, presses, and demolds bricks, eliminating the need for manual intervention. The daily brick production capacity exceeds 60,000, far exceeding customer expectations. The machine's molds are manufactured using high-precision processing techniques, allowing for interchangeable molds of varying specifications to meet customer needs and produce a wide variety of building brick types. Furthermore, the machine's optimized vibration system allows for adjustable frequency and amplitude to suit different raw materials and brick types, ensuring high strength, a smooth appearance, and minimal dimensional error in bricks that fully comply with national standards for building bricks. Furthermore, the machine's compact structure and small footprint make it easy to maintain, with quick and simple replacement of wearing parts, effectively reducing maintenance costs. Implementation Results

Since the commissioning of this set of mixing and brick-making equipment, significant improvements have been achieved for customers:

Production efficiency has been significantly improved. The mixer mixes 50 cubic meters of concrete per hour, and the brick-making machine produces 65,000 bricks per day. This represents a production efficiency increase of over 60% compared to the original equipment, enabling the company to meet the high demand for construction bricks in the local market and further expand its market share.

Product quality has been significantly improved. The quality of the mixed concrete is uniform and stable. The bricks produced by the brick-making machine have a strength of over MU15, a smooth appearance, and a dimensional error within ±1mm. The product qualification rate has reached over 99.5%, earning unanimous praise from local construction engineering companies and significantly enhancing the company's brand awareness and market competitiveness.

The equipment has operated in a coordinated and stable manner. Since its commissioning, the two sets of equipment have worked seamlessly together, with a low failure rate, an average monthly maintenance time of less than 3 hours, and an equipment utilization rate of over 97%. This has reduced production losses caused by equipment failures and ensured the company's production continuity. This reduced the company's production costs and employee workload. The equipment is simple and convenient to operate, enabling automated production. The company has reduced its workforce by five operators, saving approximately 300,000 yuan in annual labor costs. Furthermore, the equipment is easy to maintain, with long lifespans for wearing parts, reducing annual maintenance costs by 25%.

The customer highly praised our equipment and services, subsequently signing an equipment maintenance and technical support agreement with us, and expressed their intention to continue using our equipment for future production expansions.