1. Client Background and Core Challenges

Client Name: A wood processing company in Indonesia

Industry: Furniture manufacturing, wood craft processing

Company Size: Medium-sized enterprise with approximately 150 employees and an annual output value of approximately RMB 80 million

Core Challenges (Pain Points):

Waste piles up and disposal costs are high: The company's daily production process generates a large amount of wood scraps, strips, and offcuts that accumulate within the factory, taking up significant space and posing a fire safety hazard. Previous disposal methods involved selling them to vendors at low prices or paying for removal companies to dispose of them, effectively creating a negative asset.

Inefficient processing and rising labor costs: Traditional shredders have a small feed opening, requiring manual labor to pre-crush large pieces of wood. This is time-consuming and labor-intensive. As labor costs rise, waste disposal becomes increasingly uneconomical.

Untapped waste value: The client recognizes that this wood waste represents a potential resource that can be converted into valuable products such as sawdust and shavings, but lacks efficient equipment to transform it. Environmental Pressure: Local environmental protection authorities are increasingly stringent regarding the handling of industrial solid waste. Careless storage or improper disposal may result in fines.

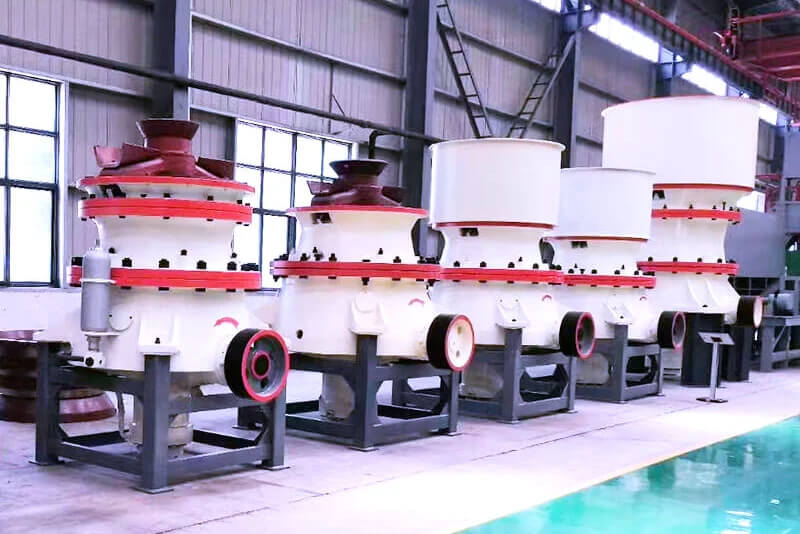

2. Solution: Introducing Our Forced-Feed Wood Chipper

After extensive research and technical comparisons, the customer decided to introduce our high-powered forced-feed wood chipper in early 2023.

Reasons for Equipment Selection:

Forced-feed system: This is a key advantage. Equipped with a hydraulically driven drum, the machine "grabs" and forcibly pushes wood planks and blocks of varying sizes and shapes into the pulverizing chamber. This eliminates the need for manual pre-crushing, significantly reducing labor intensity and safety risks.

High-capacity design: It can process 2-3 tons of wood waste per hour, perfectly matching the customer's daily waste production volume and achieving "daily clearance and completion."

Controllable output particle size: By changing the screen with different apertures, the output particle size can be easily controlled, producing wood chips suitable for different applications (such as biomass pellet fuel, particleboard raw material, livestock bedding, etc.), maximizing product value. Powerful and Durable: Utilizing a high-power motor and heavy-duty blades, it easily shreds wood containing small amounts of nails and other impurities (such as scrap pallets and furniture frames), offering long blade life and low maintenance.

Safe and Environmentally Friendly: The equipment is equipped with safety devices such as overload protection and emergency stop. The entire shredding process takes place within a sealed chamber, minimizing dust emission. A dust extraction interface is also available, ensuring a cleaner working environment.

3. Implementation Results and Return on Investment (ROI)

Since the equipment went into operation, XX Wood Industry has undergone a fundamental transformation in its waste management process:

1. Significant Economic Benefits:

Transforming Expenses into Revenue: Previously, the company spent approximately 100,000 yuan annually on waste removal. Now, the shredded, high-quality wood chips are sold to local energy companies as biomass fuel feedstock at a stable price of 300 yuan per ton, generating approximately 250,000 yuan in additional revenue annually.

Increased Efficiency and Reduced Labor: A waste treatment process that once required three workers to spend the better part of a day can now be completed by a single operator in 2-3 hours. This results in an annual labor cost savings of approximately 80,000 yuan. 2. Outstanding Management and Environmental Benefits:

Improved Factory Environment: The factory has become cleaner and more organized, fire safety hazards have been eliminated, environmental protection requirements have been met, and the company's image has been enhanced.

Achieving a Circular Economy: The company has successfully transformed "waste" at the end of production into "resources" at the front end of the supply chain, achieving a micro-circulation within the company and aligning with the concept of green manufacturing.

Simplified Management: The waste handling process has been standardized and simplified, reducing the management burden.

4. Customer Testimonials

The Production Supervisor said:

"This forced-feed pulverizer has completely changed our view of 'waste.' I used to be troubled by the sight of piles of scrap, but now we see them as 'money.' The equipment is powerful, consumes waste quickly, and most importantly, is safe and labor-saving. Workers no longer have to risk pulverizing the material. This is more than just a machine; it's a key step in our efforts to reduce costs, increase efficiency, and achieve green transformation."