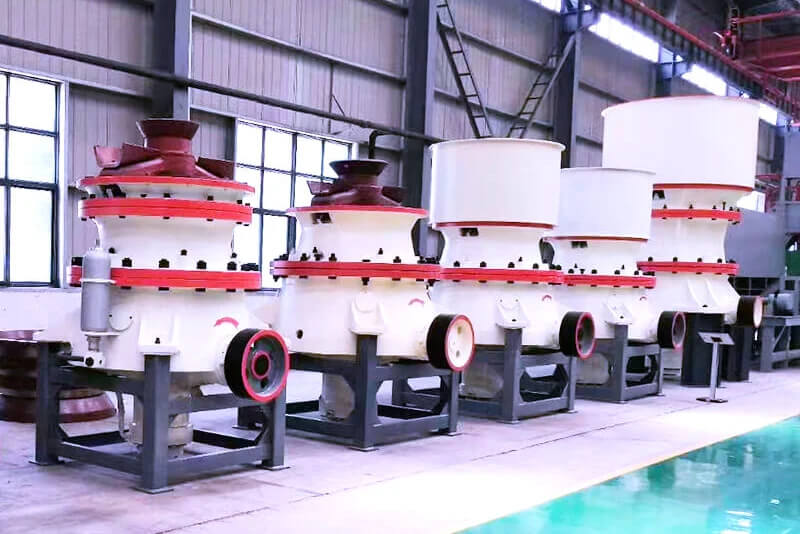

SH(S) series single-cylinder hydraulic cone crusher is developed with advanced crushing technology, integrating mechanical, hydraulic, electrical and intelligent control, Internet control system and other technologies. The new crusher structure, optimized laminated crushing cavity, intelligent automatic control system and innovative Internet control system make SH(S) series single-cylinder hydraulic cone crusher have the performance characteristics that traditional cone crushers do not have. It can be widely used in medium crushing, fine crushing and ultra-fine crushing operations.

It is suitable for crushing all kinds of ores and rocks with high and over-medium hardness in medium,construction,water and electricity,transportation,chemistry and building material industry.Especially in the metal ore and construction of sand and gravel material is the most widely used.

Strong crushing force

The main shaft of the hydraulic cone crusher is supported at the upper and lower ends, which can bear larger crushing force and larger stroke.

Good particle shape

The equipment adopts the unique crushing cavity type and the principle of lamination crushing, which produces the crushing operation between particles, improves the product particle shape and the product shape is cube.

Strong reliability

The advanced hydraulic technology realizes the integration of overload protection and hydraulic adjustment of the discharge port, which simplifies the structure of the crusher, reduces the weight and enhances the reliability.

Designed to be greener

The internal pressure of the crushing chamber of the single-cylinder cone crusher is higher than the external pressure design, which reduces the leakage of dust from the body, and at the same time, the noise reduction equipment is installed to reduce the noise and achieve the production standard of green environmental protection.

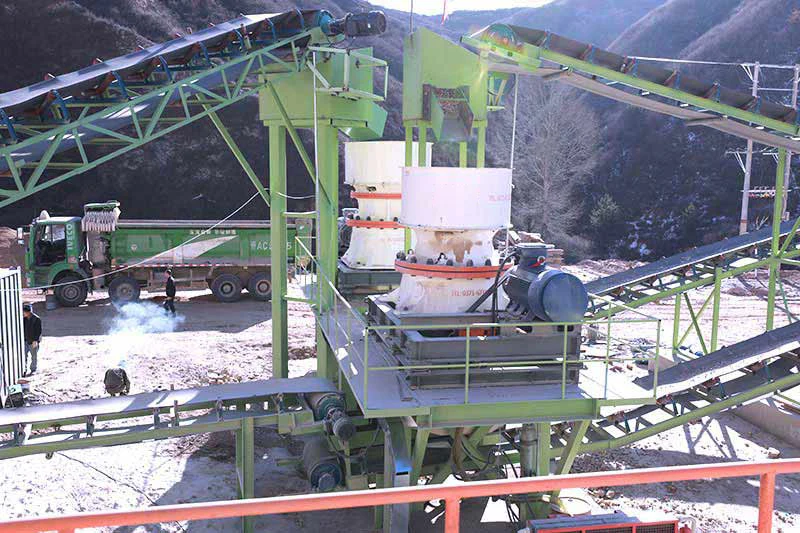

WORKING PRINCIPLE

The electromotor leads the eccentric sleeve to rotate by the V-belt, drive shaft and drive gear. The movable cone does rotary and pendulum movement under the leading role of eccentric sleeve which makes the movable cone and fixed cone close and far away from time to time. The raw material is crushed in the crusher chamber by squeezing and striking continuously. The crushed stone discharges from the bottom.