Client Background

The town of Wunsiedel in Bavaria, Germany, is a renowned European "Carbon Neutral Model Town." Its utility company, SWW, operates 700 hectares of forest resources and a biomass energy system. As the town's green hydrogen project progressed, the existing wood chip processing equipment encountered significant bottlenecks: First, the conventional shredder could only process branches under 20 cm in diameter, resulting in a utilization rate of less than 30% of the large trunks produced by forest tending. Second, the uneven particle size of the shredded wood chips resulted in a biomass pellet yield of only 82%, increasing energy consumption for subsequent processing. Third, the equipment's low level of automation required six workers working in shifts, resulting in high labor costs.

Client Requirements

1. The shredder must be compatible with a variety of wood materials with diameters ranging from 0 to 50 cm, including trunks, branches, and waste from wood processing plants, increasing raw material utilization to over 90%.

2. The particle size of the shredded wood chips must be controlled between 3 and 5 mm, with a uniformity error of no more than 1 mm, ensuring a biomass pellet yield of over 95%. 3. Automating the entire crushing, screening, and conveying process, reducing the number of operators to less than two people, and connecting the equipment to the town's energy management cloud platform.

4. The equipment's energy consumption must be reduced by 20% compared to the existing system, in line with the town's "ultimate energy conservation" development philosophy.

Solution

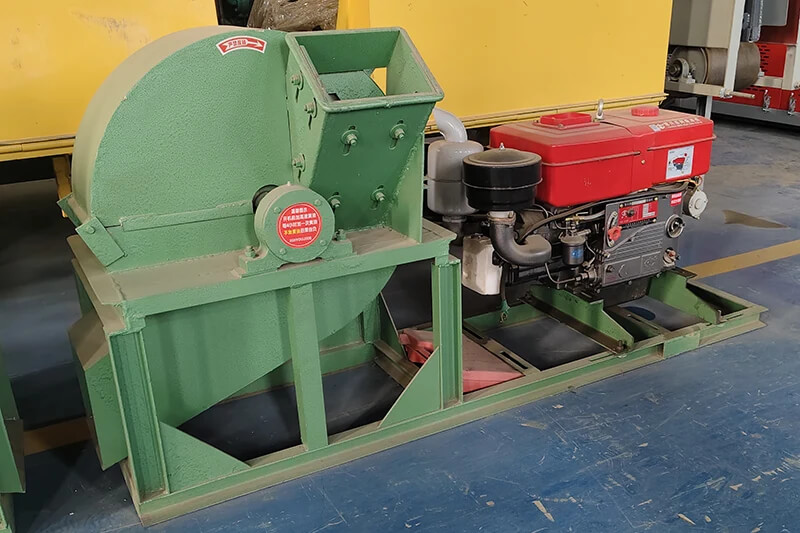

We tailored a smart biomass crushing and processing system, featuring the MF-800 multifunctional wood crusher and an integrated intelligent screening and conveying module:

1. Multifunctional Crushing Unit: The MF-800 crusher utilizes a three-stage crushing structure: a first-stage knife roller crushes coarse wood trunks, a second-stage hammer crushes fine material, and a third-stage screen screens for grading. Equipped with an extra-large 50cm diameter feed port and a hydraulic feed mechanism, it automatically pushes coarse and heavy materials. Powered by a 220kW high-efficiency, energy-saving motor, it reduces unit energy consumption to 1.2kWh/t. 2. Intelligent Sorting System: Equipped with three layers of side-tensioned screens, the system covers an area of 9.3 square meters. Screening accuracy is controlled by an adjustable vibration frequency (50-80 Hz), and unqualified materials are automatically returned to the furnace for re-crushing. The system is integrated with the town's energy cloud platform, enabling real-time upload of data such as production output, energy consumption, and particle size.

3. Automated Control: A PLC programmable control system enables coordinated adjustment of raw material feed, crushing intensity, and screening frequency. Equipped with remote fault diagnosis, the cloud platform provides 48-hour advance warning of the need for replacement of wearing parts.

Implementation Results

Since its commissioning, the equipment has seamlessly integrated into the town's energy ecosystem, generating significant benefits:

1. Wood raw material utilization has increased from 30% to 92%, enabling the processing of an additional 1,200 tons of forest waste per month, providing a stable raw material supply for the biomass pellet plant. 2. Sawdust particle size uniformity reached 96%, and the biomass pellet formation rate increased to 97%. The production cost of pellet fuel was reduced by €18 per ton, resulting in annual savings of approximately €216,000.

3. The implementation of a "one-person, automated operation" model reduced labor costs by 67% and equipment energy consumption by 23% compared to the original system, meeting the town's carbon neutrality goals.

4. The crushed sawdust is not only used to make pellet fuel but also provides biomass gasification feedstock for the local green hydrogen project, helping the town achieve a closed energy cycle of "sawdust-electricity-green hydrogen." This project has become a benchmark for biomass energy utilization in the EU, attracting 12 European towns to visit and learn from it.