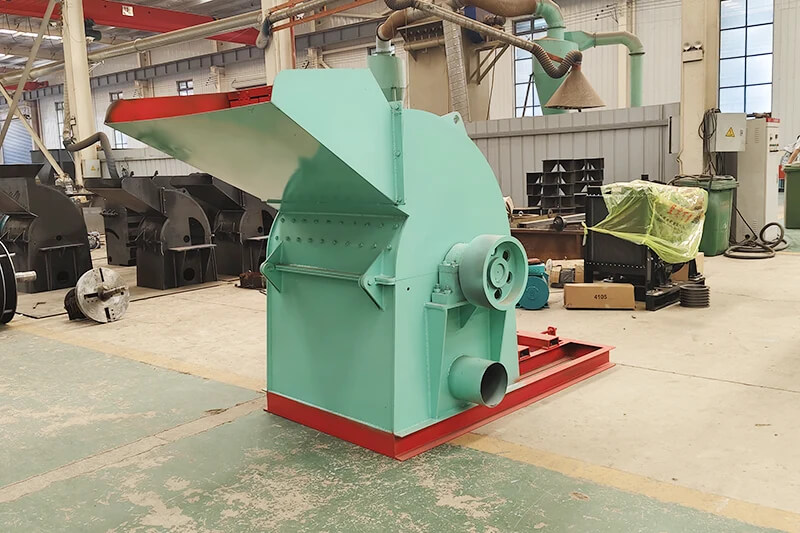

Wood chip crusher, also known as mushroom wood crusher, is the ideal wood processing equipment for processing raw materials for edible fungi.

Mushroom wood crusher covers an area of small, reasonable and compact structure layout, is very suitable for mobile operation, especially for the edible fungi raw materials such as fruit wood, elm and other hardness of wood has a very good crushing effect, is the individual business households and light industry planting edible fungi base of the ideal edible fungi processing equipment.

Working Principle

Pulverizer using blade cutting and high-speed airflow impact, collision dual-crushing function in one, and can simultaneously complete the micro-feeding sorting process. In the blade cutting and crushing process, the rotor generates high-speed airflow, rotating with the direction of the blade cutting, the material accelerated in the airflow, and repeated impacts to make the material at the same time by the double crushing, accelerating the rate of crushing of materials.

Scope of application

Pulverizer can process edible fungi, mushroom wood, fungus, pine, wood, poplar, cedar, bamboo, etc., the machine has a compact structure, covers an area of small, good crushing quality, low power consumption, and is suitable for mobile operation.

Product features

1. the machine is composed of several sets of blades, the material through the high-speed rotation of the blade will be crushed.

2. the processed raw materials into the feeding port, through the rotation of the wind blade in the machine, forming a self-absorbing feed, and better to improve the agreed safety factor.

3. The fineness of this machine is adjusted according to the size of the aperture at the bottom of the sieve. The output is based on the size of the finished product you need to determine, the larger the finished particles the greater the output.

4. Edible fungi crusher can process raw materials such as edible fungi and mushroom wood into wood chips at one time, which has the advantages of less investment, low energy consumption, high productivity, good economic benefits, and easy to use and maintain.