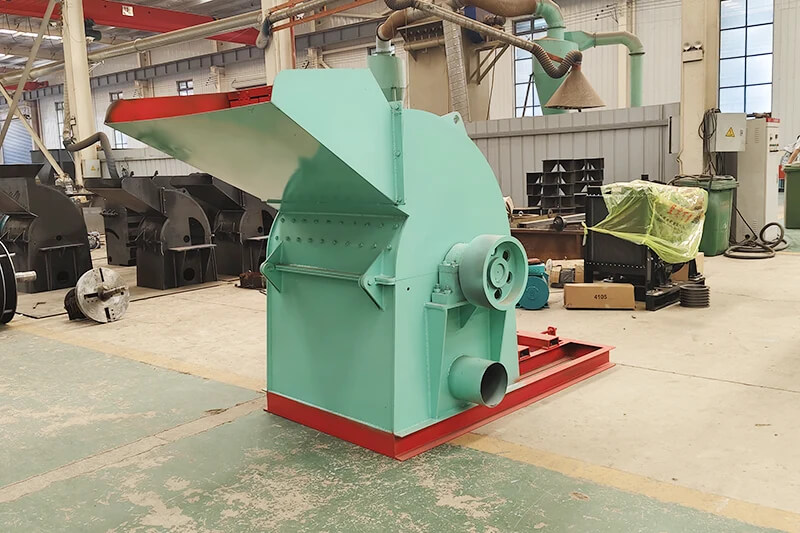

The wood crusher has reasonable design, compact structure, safety, durability and high efficiency, and has been widely used with good results. The whole set of equipment is driven only by an electric motor, low noise, simple structure, compact layout, cheap price, stable work, low energy consumption, high yield, good quality of wood chips, low processing costs.

Wood crusher adopts blade cutting and high-speed airflow impact, collision double crushing function in one, and can simultaneously complete the micro-material sorting process. In the blade cutting and crushing process, the rotor generates high-speed airflow, rotating with the direction of blade cutting, the material accelerated in the airflow, and repeated impacts so that the material is subjected to double crushing at the same time, accelerating the rate of crushing of materials.

Product structure

1, by the feeding mechanism, crushing chamber, discharge part of the three major components.

2, the pulverizer is divided into two types of single-port and double-port.

3、The attached machine is composed of fan, powder collector and dust collector.

4, the host crushing chamber by the rotor, hammer blade, screen; or knife plate, there are coarse crushing, fine crushing and centrifugal repetitive crushing, driven by the motor crusher rotor high-speed operation, so that the mechanical generation of high-speed airflow on the crushed material to produce high-intensity impact, compression, cutting force, friction, to achieve a unique crushing function.

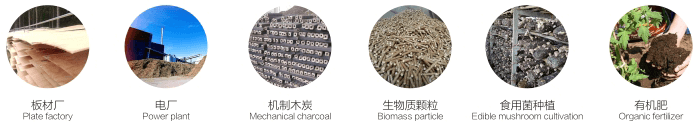

Scope of application

Wood crusher can be crushed pine, miscellaneous wood, wood, cedar, cedar, bamboo and other types of wood, can also be used for bamboo, thatch, corn stalks, sorghum stalks and other fibrous culm materials are widely used in papermaking, edible fungi, charcoal, particle board, sawdust board, high density board, medium fiberboard and other industries.

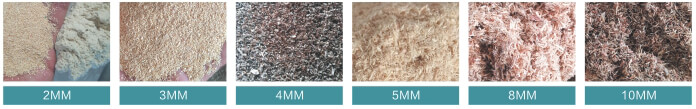

Crushing Effect

Performance characteristics

1、 Simple structure, compact arrangement

2、Cheap price, low processing cost

3、Stable work, low energy consumption

4、High output, adjustable size of discharging material, good quality of finished products.