Products

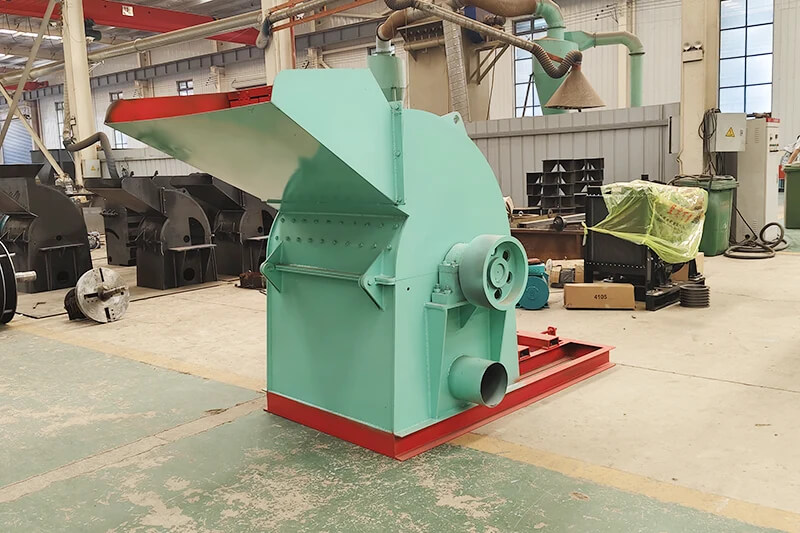

Comprehensive template crusher breaks the traditional process structure mode, the use of hammer head pounding principle, the use of the crushing mechanism, effectively preventing the bamboo glue board, the presence of nails on the pallet of goods on the impact of the equipment, can be crushed into the material into the size of 50-80mm. Due to the raw material is large, the use of all thickened screen, screen holes can only be processed 22 mm aperture, so the finished material processed is a little big, belongs to the coarse broken, hourly output of 5-10 tons or so, to crush the sawdust-like, or even finer, then you have to use sawdust crusher, the use of small aperture screen, supporting the use of the machine.

Working Principle

Comprehensive template crusher This machine adopts chain plate type intelligent feeding, which can automatically adjust the feeding speed according to the load of the main motor. It makes the machine run at full load to avoid no-load operation, makes the feeding smoother, improves the production capacity substantially, and is the ideal recommended equipment for biomass power plant. Comprehensive wood crusher equipment is widely used in waste template processing plant, bamboo glue board processing plant, artificial board factory, composite board factory, power plant boiler raw material combustion and so on, as well as individual wood processing plant use. Wood crusher can also be crushed into the size of about 5 ~ 8 centimeters in size, the use of all-steel flying knife or dollar knife hammer head, this equipment to adapt to a wide range of raw materials, high yield, can be about 10 ~ 15 tons per hour, the finished product is used as a biomass power plant as raw materials for combustion.

Performance Advantages

The machine is suitable for materials such as waste packaging boxes, templates, plates, branches, wooden crates, pallets and other materials. It is more powerful, solid and durable, with wide applicability of materials, outstanding function, convenient operation and repair, and is a green and low-carbon equipment. Comprehensive crusher has a mobile mode of operation and fixed mode of operation, flexible and versatile, to meet the needs of users, mobile biomass crusher has the advantage of being able to move at any time, the power configuration by the original motor-driven, changed to diesel-driven, more flexible and convenient.

Application Fields

Comprehensive template crusher can be processed with nails wood, wood pallets, construction site waste templates, wood pallets, stumps, waste furniture, branches, wood, template waste, housing demolition waste, doors and windows, etc. for crushing. Mainly used biomass integrated crusher can process wood with nails, wood pallets, construction site waste templates, wood pallets, tree stumps, waste furniture, tree branches, wood, template waste, housing demolition waste, doors and windows, and so on for crushing. It is mainly used for biomass power plant, making fuel, burning fire, etc. as coarse crushing, and can process wood with nails, wooden pallets, construction site waste templates, wooden pallets, stumps, waste furniture, branches, wood, template waste, housing demolition waste, doors and windows, and so on for crushing. Comprehensive crusher crushed materials are widely used in biomass pellets, artificial board, mechanism of charcoal, organic fertilizer and other primary raw materials, but also power plants, biomass pellet factories, artificial board factories and other raw materials needed, in addition to landscaping work in the need for equipment, free of foundation operation, the equipment can be landed on the job, single motor driven, saving power at the same time save electricity.