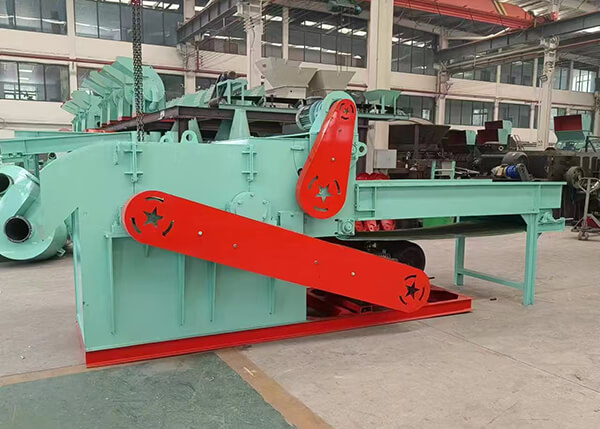

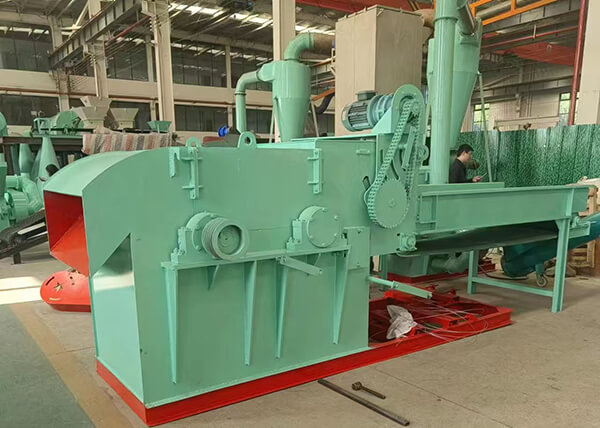

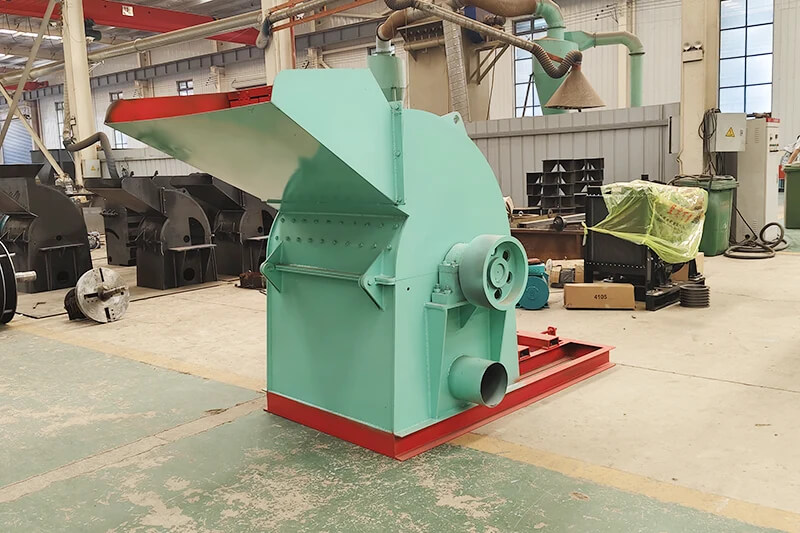

Double rotor pulverizer is for different wet and dry materials, especially the proportion of wet wood, dregs, etc. Improved screenless pulverizer.

Machine in and out of the material more smoothly, automatic forced feeding, raw materials are not limited by length, fluffy round wood and other complex materials can be crushed. Mainly applicable to: paper mills, wood processing plants, grass processing plants, bio-pellet combustion plants, ethanol companies, straw storage centers, straw processing plants, biomass new energy companies, agricultural companies, comprehensive utilization of crop straw and other plants.