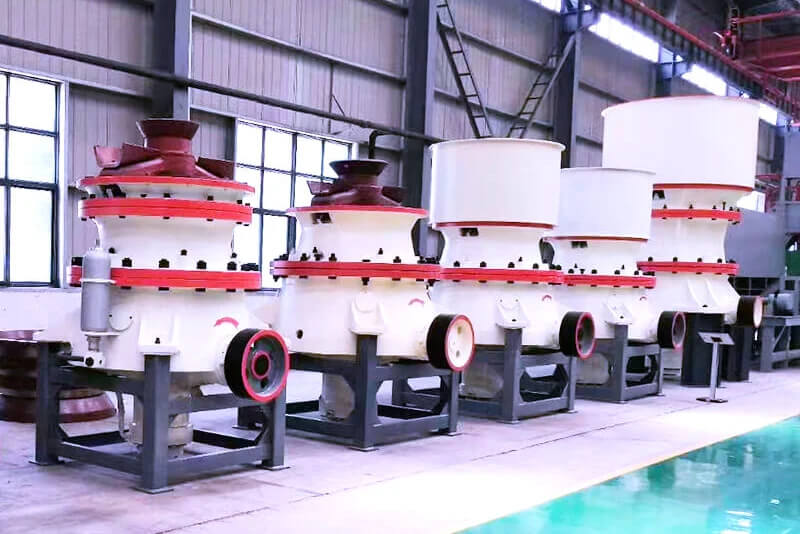

VSI crusher can process the following materials such as iron ore, copper ore, gold and silver ore, zinc, manganese, limestone, granite, basalt, cobble, coal, quartz and so on, which is widely used in the fields including rocks, abrasive, refractory, cement clinker, quartz, iron ore and concrete aggregate, building materials and so on.

Features

1.Oil supplied by two oil pumps, stops automatically if there is no oil; cooled by water, heating the motor firstly if start the machine in winter.

2.Hydraulic lifting when changing or checking the spare parts which makes it easy and convenient in maintenance.

3.Famous brand SKF or TIMKEN of the bearing makes the machine work well and few problems.

4.Vibrating alarm device; if the crusher works abnormally, alarm will sound to make the machine stop working so as to protect the crusher.

5.Special feeding structure; rock on rock, and rock on iron in the crusher making the stone to be crushed and reshaped.

6.Unique dustproof seal system, protects the lubrications parts from the dust outside.

7.Perfect design on material bumping angle reduces the friction between raw material and quick-wear parts, prolongs the service time of quick-wear parts and cuts the cost.

Advantage

1. Main shaft is equipped with imported precision rolling bearing.

2. Hydraulic lifting mechanism of upper cover can move away the cover easily.

3. Advanced double-pump oil lubrication system guarantees shaft bearing lower temperature increase, longer life time, more reliable operation.

Applications

The Vertical Shaft Impact Crusher is an advanced and high-efficiency equipment. It is the latest researched results basing on Germany technology. The machine is professional in producing qualified sand and stone for highway, high-speed railway, high building, city project, hydropower dam constructions, and concrete mixing plant. It is the best choice for sand making and stone reshaping industry.

Principles

Entire Center Feeding: Materials fall into the hopper of VSI, then get into the high speed rotating wheelie through center feeding hole. Materials are speed up rapidly in the wheelie, the speed can be dozens of times of gravity acceleration, then shoot out at high speed and hit against the materials falling free after being rebounded, then they are all impacted to the liner layer of materials to strike against each other, or to the counterattack board to be bounded oblique upward to the top of the eddy current cavity, then change their heading, deflect and move downward, then strike against the materials shot out from the impeller passage, which forms continuous material flow. So the materials are hit, rubbed and grinded for two or more times in the eddy current crushing cavity. The crushed materials are discharged from the lower outlet.