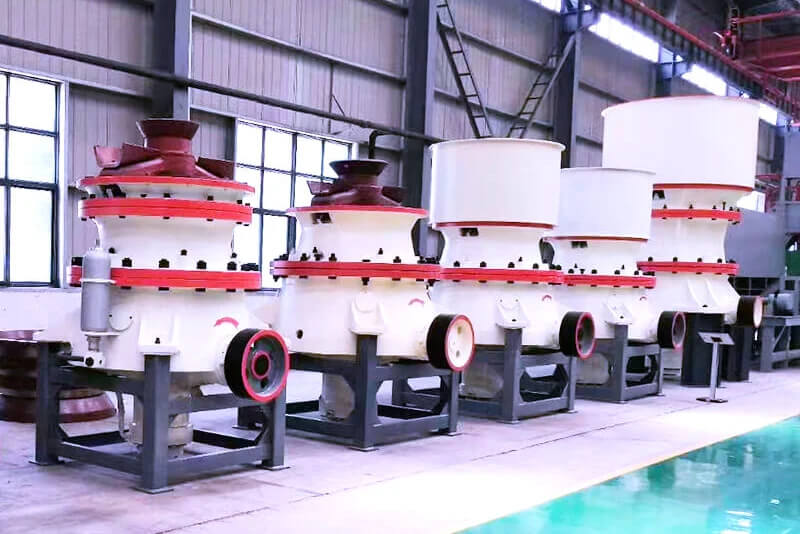

Production Capacity: 100 - 600t/h

Application Areas: Metal and non-metal ores, building materials, artificial sand making, metallurgical slag

Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, calcite, quartzite, diabase, coal, calcium carbide, etc.

Product Features

The 6X series vertical shaft impact crusher is a new type of sand - making and crushing equipment that absorbs years of R & D experience and technical concepts. It adopts a brand - new four - port impeller design structure and a special sealing structure to prevent oil leakage in the bearing barrel. It has the characteristics of energy - saving, long service life, and wide application, helping large sand yards gradually move towards large - scale and centralized production to meet the national requirements for environmental protection and production capacity.

Advantages and Highlights

Easy Maintenance

A new lifting device is added to facilitate customers' equipment maintenance, saving labor and effort in maintenance and repair. The simple lower structure design of the machine effectively prevents the lower part of the machine from being blocked when the water content of the material is too high, reducing downtime.

Special Design, Quality Assurance

The transmission part of the equipment adopts a special sealing structure to prevent oil leakage in the bearing barrel, and imported bearings are used to reduce failures of the transmission system.

Process Upgrade, Cost - Reduction and Efficiency - Increase

The "stone - on - stone" working mode is adopted to reduce the types of wear - resistant materials used, reducing customers' production costs. The structure and process of the impeller part are adjusted, and the service life of the impeller part under the condition of crushing the same material is increased compared with previous equipment.

Brand - new Design

The impeller structure adopts a brand - new four - port design, which increases the material throughput and improves the crushing efficiency of the same material compared with the three - port impeller.