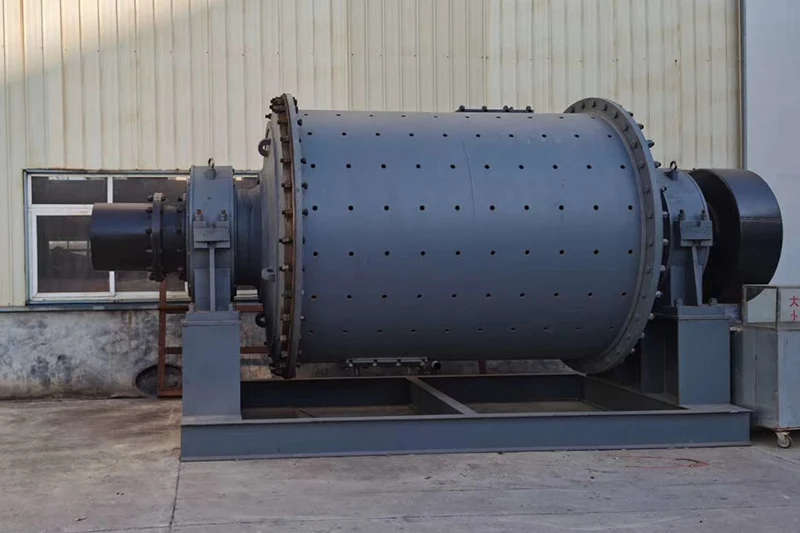

Overflow ball mill has the advantages of relatively simple structure - no grid, high fineness of grinding, relatively fewer balls, etc. It is widely used in the second stage of fine grinding or occasions requiring relatively fine products.

When the electric motor drives the cylinder through the pinion gear and large gear, the material is fed into the cylinder from the left end through the hollow journal via the feeder. The cylinder is equipped with a certain quality of steel balls as the grinding medium. The material is crushed by the action of steel balls, and then discharged out of the machine through the hollow journal at the discharge end. Since the crushed product is discharged through the overflow of the hollow journal, this kind of ball mill is called overflow ball mill, which is a kind of widely used ball mill.

Overflow ball mill structure and lattice type ball mill is basically the same, just in the cylinder discharge end without discharge lattice, and then, in the hollow journal liner surface is equipped with anti-spiral blade, can be overflowed in the slurry of small balls and coarse ore back to the mill, overflow ball mill grinding product is free to overflow through the discharge of the hollow journal. For this reason, the level of the slurry in the cylinder must be higher than the level of the bus of the discharge journal, so it is sometimes called high slurry liquid level mill. Overflow ball mill has simple structure, convenient operation and maintenance, and the product is fine, commonly used in fine grinding, that is, the fineness of grinding less than 0.2mm or the second section of two continuous grinding.