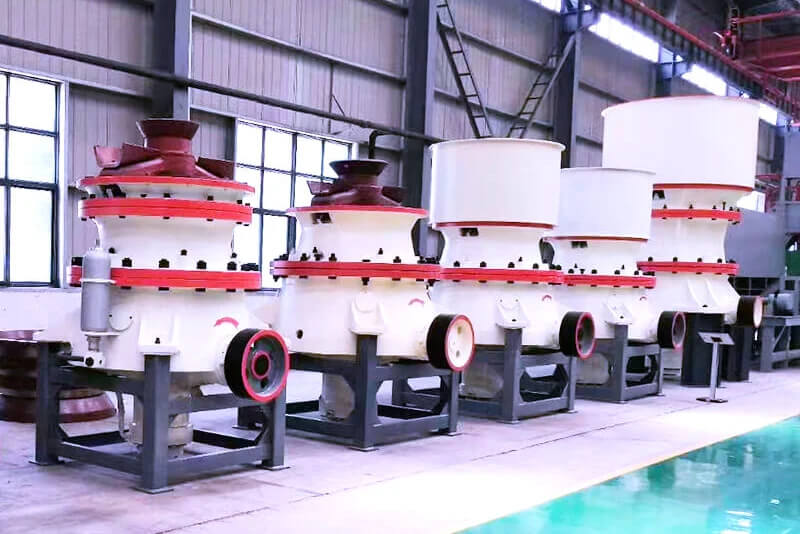

CS Series Cone Crusher concentrates on the specialty of high-frequency, optimization of cavity and reasonable impact. It is based on the conceptions of laminated crushing principle and more crushing and less grinding. It is researched and designed by our company, according to the customers’ requirement. This CS series cone crusher is widely used to crush metalliferous and nonmetalliferous ores, cement, construction and sand. The standard model is suitable for medium crushing, and the medium model is suitable for fine crushing and the short head model is suitable for fine crushing.

A variety of cavity types are available for a wide range of applications

The compound cone crusher consists of standard type and short-head type. Each type has four crushing cavity types: coarse, medium, fine and ultra-fine. It can crush materials with medium hardness or above.

High yield and uniform grain shape

It adopts the principle of lamination and crushing and the concept design of more crushing and less grinding, so that it has higher output than the same type of machine, and the particle shape of the crushed material is more uniform.

Low failure and less downtime

Through the use of hydraulic insurance, hydraulic locking, hydraulic adjustment, hydraulic cavity cleaning and other devices, the operation becomes more automatic. The equipment adopts an optimized design. Under normal use conditions, the trouble-free operation rate exceeds 95%, which greatly improves the production efficiency. .

Robust components for reliable operation

The body of the compound cone crusher is of casting structure, and there are reinforcing ribs at the high stress points of the heavy load parts. The independent thin oil lubrication system and automatic control make the equipment more durable and reliable in operation.

WORKING PRINCIPLE

In the working process of the cone crusher, the motor drives the eccentric sleeve to rotate through the drive, and the moving cone is rotating and swinging under the forced motion of the eccentric shaft. The moving cone is close to the section of the static cone and becomes the crushing chamber. The material is broken by the multiple extrusion and impact of the moving cone and the static cone. When the moving cone is away from the section, it has been crushed to the required size, and the material is falling under its own gravity and discharged from the cone bottom.