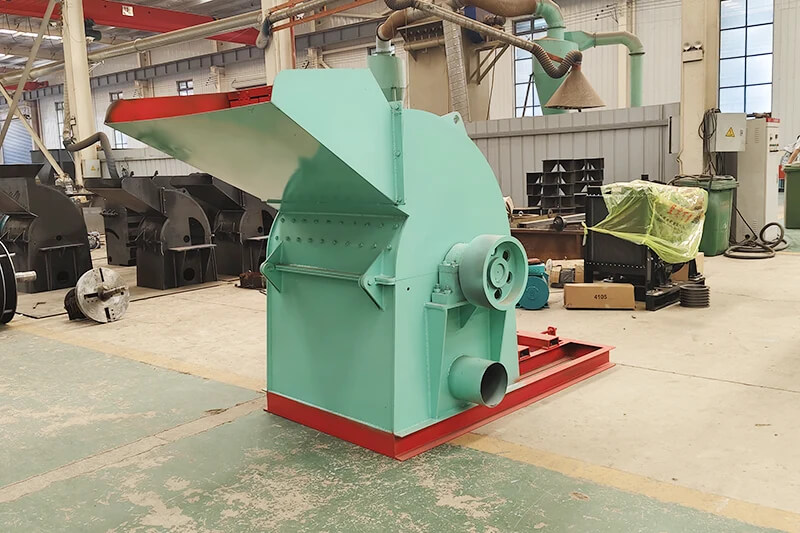

Tree root crusher is a crushing machinery equipment to crush all kinds of tree roots, tree stumps, wood stumps, tree lumps. Tree root crusher is also called wood pier machine, pier machine. It is a kind of faster, wood crushing and processing equipment. The machine has a compact structure, small footprint, chipping, low power consumption, and suitable for mobile operations. Models are: 3000, 4000 type motor fixed version, diesel mobile version.

Customers can not need to organize the processing of large tree roots, tree poles, do not need to split the wood first processing treatment, directly after the tree root crusher one-time processing, the processed material can be sent to the biomass power plant to do the use of fuel, but also with a small crusher secondary crushing to do other molding use.

Applicable materials

Working Principle

When the disc root crusher is working, the rotor is driven by the motor/diesel engine to rotate, and the feeding hopper is also driven by the motor/diesel engine to rotate slowly, the material is put into the hopper through the grasping machine, and the material teeth on the inner wall of the hopper will uniformly dial the material to the rotor at the same time while rotating, and the material is touched by the high-speed rotor to achieve the preliminary crushing of the material by the cutting and tearing of the rotor blades, and the material will fall through the screen in the crushing chamber under the action of its own gravity and rotor impact, and the material will be discharged through the screen to meet the requirements. After preliminary crushing, the crushed materials will not fall on the screen in the crushing chamber under the action of its own gravity and the impact force of the rotor, and the materials that meet the requirements will be discharged through the screen, while the materials that do not meet the requirements will be crushed in the crushing chamber for the second or even the third time until they meet the requirements.