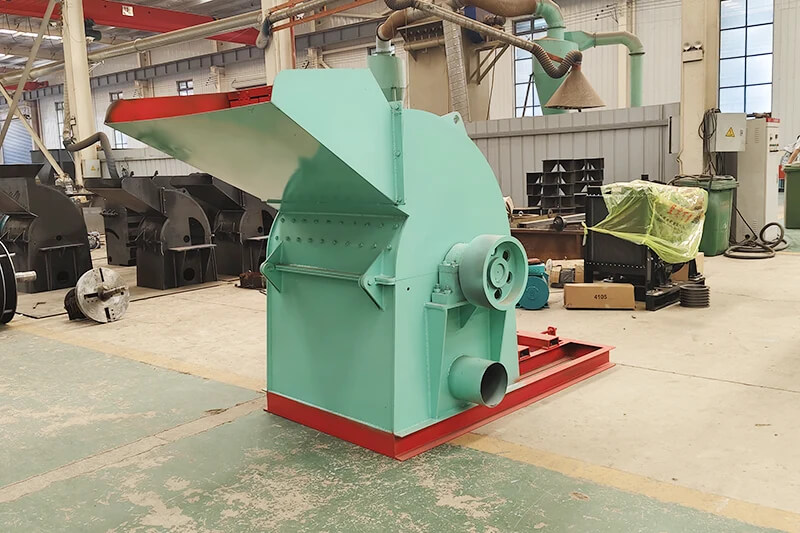

Product introduction

The shredder adopts microcomputer (PC) automatic control system, with the functions of starting, stopping, reversing and overloading automatic reversing control, featuring low speed, large torque, low noise, etc. The bearing seat adopts folio type, which is suitable for shredding very large and thick materials. The bearing seat adopts folio type, which is easy and convenient to disassemble and change knives, and is suitable for shredding extra large, extra thick and hard-to-break materials. Shredder cutter material is high-density alloy tool steel and high wear-resistant mold steel, durable; reducer using hardened gear surface of the national standard series, the motor is used in Nanjing control of the special, are well-known brands, the machine warranty of one year.

Working Principle

The shredder adopts a gear motor directly connected to the worm gear, directly mounted on the main shaft of the crusher, through the size of the gear speed to the transmission shaft, so that the main transmission shaft on the helical teeth of the disk to form a relative movement. Spiral teeth on the main drive shaft disk staggered arrangement, so that the material enters, at the same time by the extrusion, tearing, shearing effect, so that the material is crushed.

Equipment features

1: Thick moving knife, high crushing power, knives are alloy tool steel and wear-resistant mold steel casting, sturdy and long service life.

2:The frame plate is thick, can resist high torque, very strong.

3:Start, stop, reverse and overload automatic reverse control function.

4: The equipment is characterized by low rotational speed, large torque, low noise, and dust can reach the environmental protection standard.

5: Easy to adjust, low maintenance cost, economic and durable.

6: The thickness of knives and the number of knife claws can be replaced according to different materials.