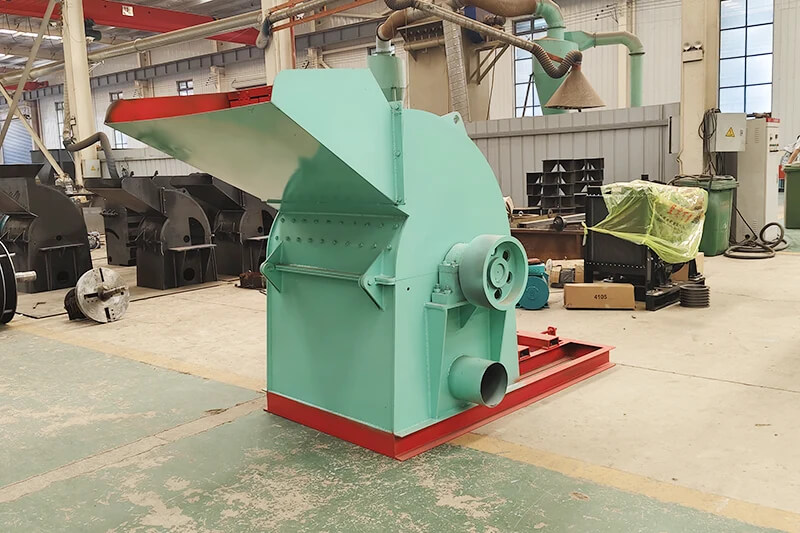

Product Introduction

Disc chipper, can be large and small raw materials, including logs, veneer, veneer, bamboo, branches, corn stalks, cotton stalks, reeds and other non-woody fiber poles into uniform flakes, the length of the flakes can be adjusted according to the needs of a certain range, which consists of a frame, the knife plate, (the knife plate is equipped with two to six flying knives) feeder, power, etc., this series of products have a reasonable structure, reliable, easy to operate, the quality of materials, high yield, low energy consumption, easy maintenance, high production efficiency, is suitable for paper mills, fiberboard plants, particleboard plants and wood chips production bases and edible fungi production raw material processing, is the ideal equipment for users. This series of products have reasonable and reliable structure, simple operation, good quality of material, high output, low energy consumption, convenient maintenance, high production efficiency, suitable for paper mills, fiberboard factories, particleboard factories and woodchip production bases and raw material processing for edible fungus production, which is the ideal equipment for users. Straight mouth woodchip machine is newly developed, the feeding mouth is changed from slanting mouth to straight mouth, which can be used with conveyor belt.

Working Principle

Wood is fed into the machine from the feeding port, and when the wood comes into contact with the cutting blade, it will be cut with the high-speed rotation of the cutting disk, and the cut wood pieces will be sent out by the high-speed vapor flow generated by the wind blade on the cutting disk in the cutting room.

Product use

Disc plane chipper (disc chipper) can cut logs, small-diameter wood and branches with a diameter of less than 200mm, suitable for pulp mills, forestry farms, paper mills, woodchip mills, etc., and can be used to process pine, miscellaneous wood, yangmu, fir, and raw bamboo, due to the compact structure of the machine, small footprint, good quality of chipping, low power consumption, and suitable for mobile operation, it is widely used in the preparation section of small and medium-sized particleboard and fiberboard production enterprises. It is widely used in the preparation section of small and medium-sized particleboard and fiberboard production enterprises, and can also be used for the production of commercial wood chips by individual households.

Instructions for use of knives

Disc chippers are divided into two types according to the number of knives on the disk: ordinary chippers (4-6 knives) and multi-blade chippers (8-6 knives). These two types of chipper feeding method and there are two kinds of slant feeding and flat feeding (or horizontal feeding). Long logs are generally fed with a flat feed, while short logs and boards can be fed with a beveled feed or a flat feed.