Drum wood chipper is a kind of wood slicer, which is the equipment for producing wood chips. This wood chipper is used in particle board factory, medium and high density fiberboard factory, straw factory, biopower plant, wood chip factory and other industries and manufacturers production in the preparation of material section of the former equipment.

Product structure

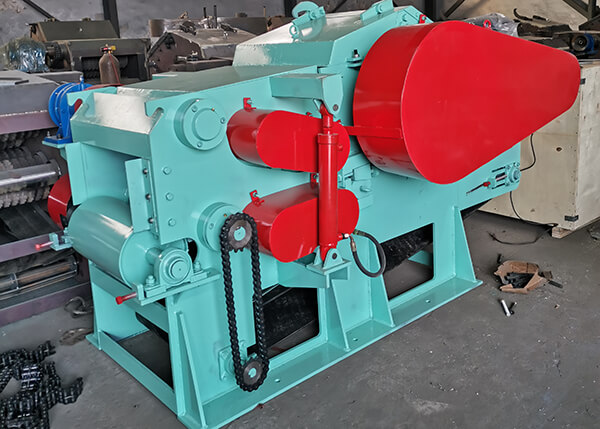

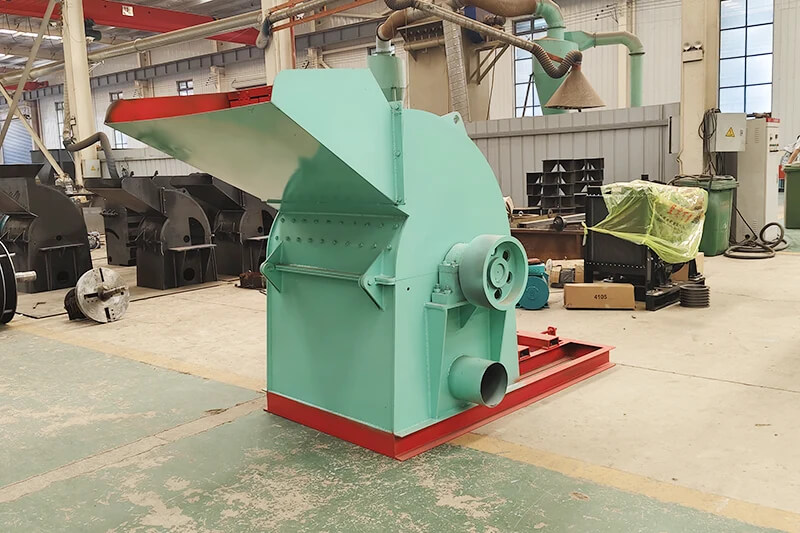

Drum chipper is not too complicated, the machine adopts the steel plate structure welded together, the whole machine is mainly composed of body, knife roller, upper and lower feed rollers, conveyor belts, hydraulic system part of the composition (excluding motor), high-strength welded plate, is the machine's support cornerstone. Drum chipper's knife roller installs two or three, four flying knives, with specially manufactured flying knife bolts, through the pressure block, the flying knife is fixed on the knife roller. According to the different thickness of the raw material to be cut, the upper feeding roller assembly can float up and down within a certain range with the help of hydraulic system. The qualified flakes cut down will fall through the screen holes and be discharged from the bottom, and the big flakes will be cut in the machine. Hydraulic system of drum chipper: supplied to the oil cylinder by oil pump, it can start the cover, which is convenient for the replacement of blades; the upper feeding roller assembly can be lifted up during the maintenance, which is convenient for the adjustment of the clearance of the fly cutter and the bottom cutter, as well as the disassembling of the comb plate.

Product features

1、Large drum chipper, wood slicer has high output, low energy consumption, high quality wood chips and high cost performance.

2, drum chipper compact structure, reasonable layout, easy to install, easy to operate and maintain, high production capacity; cutting logs, high quality of wood chips, and the length of the wood chips can be freely adjusted within the specified range of industrial machinery and equipment.

3, drum chipper output, users can choose their own models according to need. Wood crusher beautiful appearance, durable, high output, than the traditional wood flour machine efficiency increased by more than 50%.

Scope of application

Drum wood chipper raw materials can be logs, small diameter wood, wood harvesting residues (branches, branches, etc.), wood processing residues (slats, veneer, round wood core, waste veneer, etc.), bamboo, cotton stalks, reeds, rice straw, wheat straw and other non-woody fiber poles and stems cut into a certain specification of flakes, as the basic raw material for the manufacture of particleboard, fiberboard, medium and high-density fiberboard, non-wood manmade boards and pulp and paper making.